Baler for cans type PBPPs500-15

baler for cans

Technical specification

Number of chambers:

single

The density for aluminum cans:

ca. 700 kg/m3

Charging hole:

310 x 770 mm

Bale launch:

automatic

Max. pressure:

500kN (50 tons)

Supply:

400/50 [V/Hz]

Unit pressure:

40,8 kg/cm2

Socket:

400/32A

Bale dimensions:

350 x 350 x 130-250 mm

Engine power:

15 kW

Bale weight:

ca. 11 - 18 kg (Aluminium can)

Weight:

4300 kg

Practical productivity:

to 410 kg/h (Aluminium can)

Załadunek:

top

Productivity

5

cykli zagęszczenia

8

cykli zagęszczenia

Bale dimensions:

350 x 350 x 130 mm

Bale dimensions:

350 x 350 x 210 mm

Bale weight:

ca. 11 kg

Bale weight:

ca. 17,5 kg

Czas tworzenia beli:

115 seconds

Czas tworzenia beli:

155 seconds

Practical productivity:

ca. 354 [kg/h]

Practical productivity:

ca. 406 [kg/h]

Density:

ca. 710 kg/m3

Density:

ca. 680 kg/m3

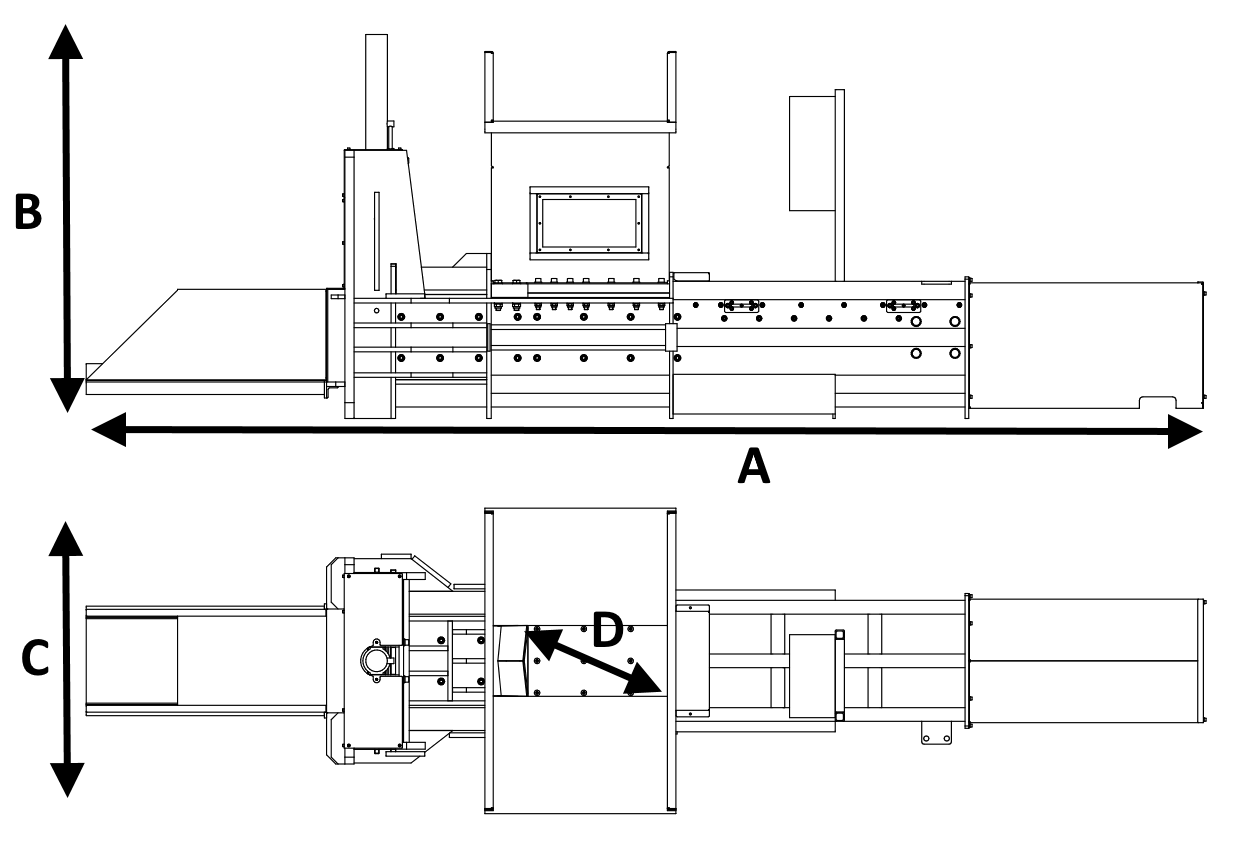

Dimension

Legend

[mm]

A

Length

4900

B

Height

1700

C

Width

900

D

Filling inlet

310 x 770

Advantages of the machine

- The moving of the pressing plate is kept extremely rigid and straight.

- The steel construction of our machines is designed to withstand loads far in excess of the rated load for the different models (this is why our machines have a generally bigger own mass compared to the competition)

- The possibility of producing specified machines concerning the customer’s request e.g. changes in the stroke of the pressing plate, changes in the loading hole, changes in the size of the bale, etc.

- No hidden costs of operating the machine

Steering

Steering

- Controller SIEMENS S7

- the ability to connect the machine to the statArtechnic

Film