Waste balers type PBPe600-o

series 1100x780

Technical specification

Number of chambers:

single

Number of strappings:

4

Charging hole:

1630 x 730 mm

Bale launch:

automatic

Max. pressure:

600kN (60 tons)

Supply:

400/50 [V/Hz]

Unit pressure:

7 kg/cm2

Socket:

400/32A

Bale dimensions:

1100 x 780 x 600-1500 mm

Fuse protection:

32C - zalecane

Bale weight:

ca. 200 - 600 kg

Engine power:

15 kW

Productivity:

ca. 2-6 bale/h.

Weight:

11 000 kg

Loading:

top

Bale tying:

manual

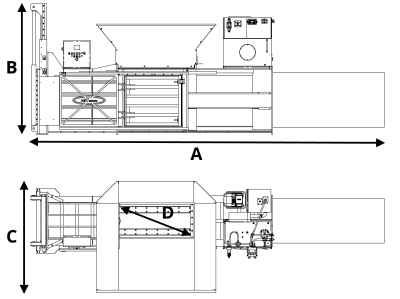

Dimension

Legend

[mm]

A

Length

7800

B

Height

2550

C

Width

2425

D

Filling inlet

1630 x 730

Innovative solutions are our speciality

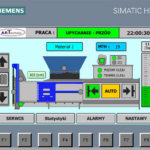

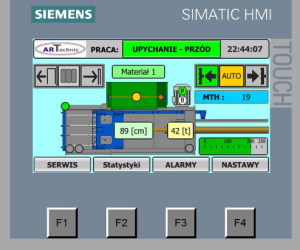

- The machine is controlled by the Siemens S7 series PLC. Thanks to this solution, we have optimized the stages of the machine’s operation and opened the way to new solutions, so far not used by other manufacturers. A large color LCD touchscreen graphically shows the bale pressing process, current operating parameters and the condition of all sensors and switches on the machine in a graphical way. The use of the latest devices of automation and control equipment made it possible to monitor the current working pressure of the machine and the position of the pressing plate. For easier diagnostics, the operating parameters are presented on a line chart. Laser measurement of the position of the pressing plate and pressure sensors with an analog output give the operator a unique opportunity to decide on the desired length of the bale and the pressure with which the baler is to act on the crushed raw material. Laser measurement of the position of the pressing plate and pressure sensors with an analog output give the operator a unique opportunity to decide on the desired length of the bale and the pressure with which the baler is to act on the crushed raw material. The new ARTechnic control means greater comfort for the operator, easier diagnostics of errors and faults, and instant adjustment of the machine’s operating parameters to each type of raw material and the requirements of the recipient of the finished bale.

- The construction of our machine has been designed to cope with loads far exceeding those arising during the daily operation of the baler, even on the most difficult raw materials. The strongest construction on the market (greater weight of the machine compared to machines from competing companies) is a guarantee of the machine’s service life and trouble-free operation for many years. Two large inspection hatches on the sides of the bale chamber allow easy access to the press plate for maintenance and cleaning, and if necessary, the press plate can be easily removed through the side hatch without having to dismantle the entire machine.

- Safety is the basis. The ARTechnic PBPe600x-o baler is equipped with the latest solutions in the field of machine safety. Emergency switches located around the machine are always within easy reach of the operator. All dangerous zones are secured with permanently attached shields or openable shields with magnetic safety sensors. A safety cable switch is installed on the baler hopper as standard, and the whole is supervised by the safety module of the German manufacturer Schmersall.

- The maintenance-free and durable hydraulic system, built on components from the best manufacturers, guarantees trouble-free operation and easy maintenance.

- Bale binding can be done with all commonly used materials, such as: polyester tape, twine or steel wire.

- We offer you the possibility of special preparation of the machine at the customer’s request, e.g. changing the stroke of the pressing plate, changing the loading opening, changing the size of the bale, etc.

- No hidden machine operating costs, such as mandatory paid inspections during the warranty period.

Steering

Steering x (EXTRA)

- Controller PLC SIEMENS S7

- Automatic digital steering of the work cycle

- Finished-bale signal

- LCD display

- Stepless maximum pressure regulation with 1 ton progression

- Stepless bale height regulation with 2 cm progression

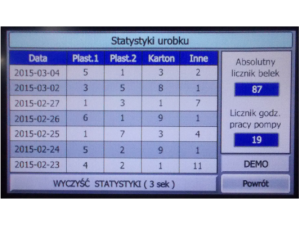

- Daily/weekly/monthly statistics – the readout of the number of finished bales with their weight estimation

- Different programs for different materials

- Possibility of regulating the length of time for which the pressing plate stays in the lower position

- the ability to connect the machine to the statArtechnic

Control Panel

Film

Tapes for bale tying

Specification:

Width [mm]

Endurance [mm]

Tape length in roll [mb]

19

725

250

6 (string)

590

220

Width [mm]

Endurance [daN]

Weight [kg]

3

<400

40